Manufacturing Execution System and Technology Integration Project

Overview

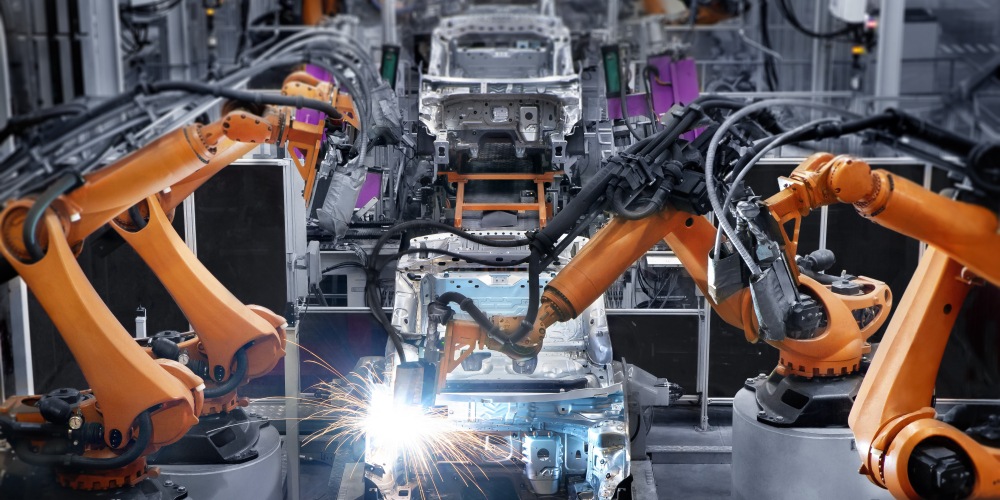

One of the flagship vehicles from a global automotive manufacturer was completely redesigned for the first time in 10 years, and built on a new chassis. To recognize additional production efficiencies, improve quality and reduces costs, the automotive manufacturer wanted to integrate the latest automation tools to support the new build process. We were awarded the tender to work as Owner’s Representative for Manufacturing Execution System (MES) integration and Information Technology integration activities for the assembly plant’s retooling program for the new vehicle model build.

Our Services

As the Owner's Representative, Comtech provided Engineering, Project Management and Technology services including the following:

- Full-Scope Project Management

- Management, Integration and Validation of Process Tooling and Factory Information System (FIS)

- Schedule Build Management

- Production Quality Reporting

- Error Proofing Implementation

- Automatic Material / Logistic Reorder Triggers (Kanban)

- Server Configuration

- Scheduling and Build Management

- Production Quality Factory Floor Machine Monitoring

- Configuration and Validation of Plant Floor Systems/Devices

- New server implementation for Final Assembly Electrical Test

- Configuration of Hardware/Software and Networks

- Configuration of OPC Software

This successful MES and IT implementation provided our client with real-time KPI’s to help pinpoint constraints and quality issues, resulting in significant production performance improvements.