Fiat Chrysler Automobiles (FCA) Manufacturing Facility Expansion

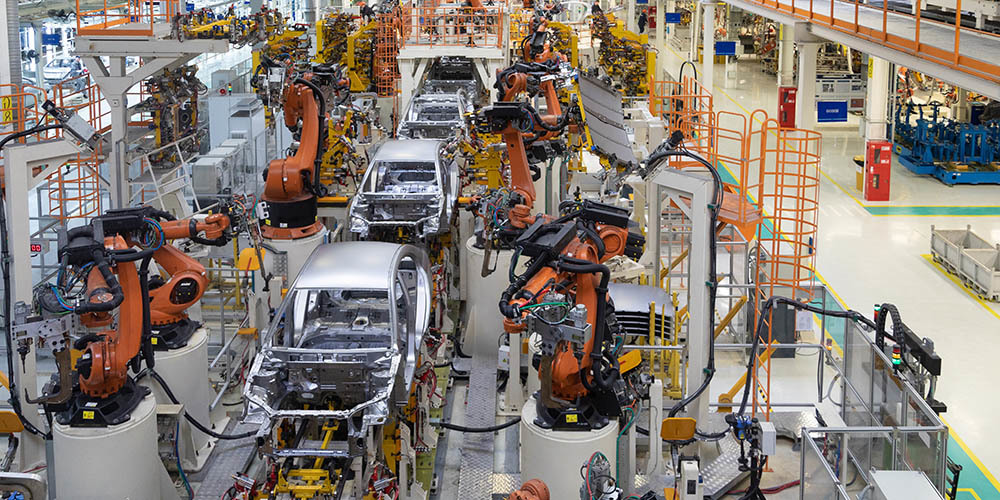

* Please note that the image above is not reflective of FCA's Manufacturing Facility

Overview

FCA invested $1.6 billion to convert the two existing Mack facilities into a new assembly site for an all-new, three-row, full-size Jeep® SUV and the next-generation Jeep Grand Cherokee. The reborn Mack Assembly Plant will be the first new assembly plant to be built in the city of Detroit in nearly three decades.

Our Services

Comtech is providing Program and Project Management and full integration of the Owner’s Manufacturing Execution System (MES) for the new assembly plant. We are bringing project management, process improvement, and engineering integration best practices applied from decades of manufacturing experience.

Our team is working collaboratively with FCA IT teams, manufacturing engineering teams, equipment manufacturers, and plant production/maintenance teams to provide and integrate the systems, tools, and data that will support world class manufacturing.

Comtech is providing full-scope Project Management, Engineering, and MES Integration Services for the new assembly plant including, but not limited to:

- Full-Scope Project Management

- Owner’s Engineer/Representation

- Schedule Development, Management, and Control

- Process Design Review, Development, and Improvement

- Controls Engineering

- Turnkey Controls Project Implementation

- Machine Diagnostic Integration

- Component Part Tracking System Integration (for Long-Term Warranty Tracking)

- Broadcast for Extension of Plant Suppliers

- Material Logistics Management Kitting and Sequencing IT Infrastructure Design

- Kanban Machine and Operator Interface Design and Implementation

- Throughput Analysis for Machine Downtime and Bottleneck Datamining

- Graphical User Interface Design or Assembly Plant Information Display Dashboards

- Operator Workstation Error Mistake Proofing

- High-Level KPI Tracking and Progress Tracking

- Machine Interface Design Responsible for Major Process Equipment and Conveyor Systems